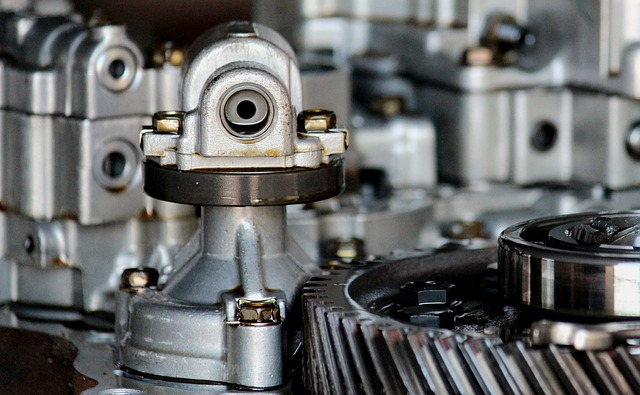

Maintenance Engineers are vital to keeping your production line running smoothly. Some jobs help companies make money, while others save money – and maintenance engineers will save you money by avoiding costly breakdowns and delays. But what should a company look for in recruiting a maintenance engineer who will keep things moving?

1. Flexible approach

The main duty of a maintenance engineer is keeping production moving. However, sometimes, machines will need servicing and worn-out parts replacing, and this means shutting things down. A good maintenance engineer however will understand the need to coordinate with other teams to carry this out – they won’t be blinkered into fixing the machines at any cost. Candidates need to demonstrate the ability to plan maintenance work to minimise down time.

At the same time however, candidates must be prepared to drop everything straight away if there is a breakdown. Getting things moving again needs to be top priority.

2. Broad skillset

If it’s top priority to get things moving, then your maintenance engineer needs to be able to fix just about anything that could go wrong. A mixed electrical and mechanical engineering background is essential, unless you have a larger maintenance team that can cover both skillsets. We often find candidates with experience in the armed forces really excel in these sorts of roles, because of their experience making repairs on the fly to get things in working order ASAP – proper, long-term solutions can be engineered at a later date!

Some formal engineering training is essential though. It’s one thing to be able to fix something in the short term, but that fix must be fit for purpose or you risk further failures as well as your other staff members.

3. Safety conscious

Production floors are high-pressure environments, and it can be tempting for many, under pressure to meet output targets, to cut corners to keep things moving. Maintenance engineers may need to work on machinery while it’s still operating, but they must be safety conscious and not afraid to say “no” to putting themselves at risk. Taking risks to make repairs can do more harm than good for a business, when it means losing health and safety accreditation, a good member of staff, and probably shutting down machinery longer than would have been necessary to make repairs.

Maintenance Engineers are a vital part of the team in any manufacturing company, and while they may cost in the short term, investing in maintenance personnel will help secure longer-term profitability for your production operations. For short chat about recruiting maintenance engineers for your business, or any advice to help you recruit and retain staff long-term, get in touch with our engineering specialist recruiter and Managing Director, Cathy Bates.